Rubber Materials: The Foundation of Electrical Safety and Reliability #

Rubber-molded products are integral to electrical applications, offering insulation against current loss and robust protection from electrical shock. The flexibility, chemical resistance, and durability of rubber materials make them a preferred choice for ensuring both safety and longevity in demanding environments.

The Advantages of Rubber in Electrical Applications #

Safety is paramount in electrical systems, and rubber stands out as a key material for achieving this. Its unique properties allow it to conform to various shapes, providing a secure fit that contains electrical currents effectively. The natural insulating capabilities of rubber act as a barrier against electrical hazards, while its resistance to moisture and dirt helps safeguard sensitive components.

Material Options and Their Distinct Benefits #

Rubber is not a one-size-fits-all solution; different compounds offer specialized advantages:

- Silicone: Known for its excellent dielectric strength and ability to withstand high temperatures, making it ideal for insulation.

- EPDM: Excels in waterproofing and moisture resistance, suitable for outdoor or damp environments.

- Neoprene: Provides fire resistance and protection against static shocks, making it suitable for volatile or hazardous settings.

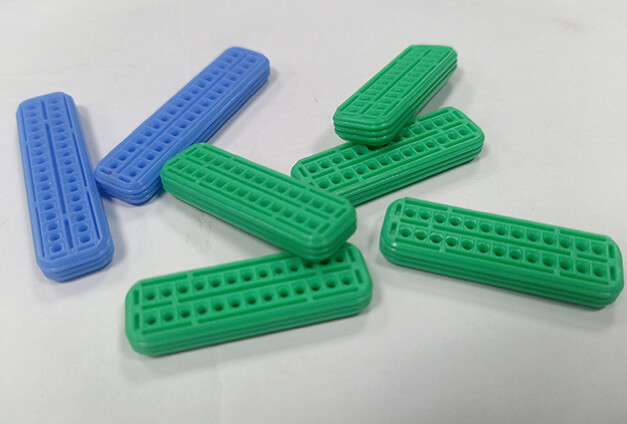

Versatile Forms for Diverse Needs #

Rubber components can be engineered into various forms, each serving a specific function:

- Seals: Prevent dust and moisture ingress.

- Gaskets: Absorb vibrations and promote smooth operation.

- Shields: Deflect electromagnetic interference, protecting data integrity.

Jhao Yang: Expertise in Electrical Rubber Components #

At Jhao Yang, we understand the critical role rubber plays in electrical systems. Our approach combines engineering expertise with a commitment to quality, ensuring that every product meets rigorous international standards such as UL and CE certification. Our team collaborates closely with clients to select the optimal material, design tailored solutions, and deliver reliable results on schedule.

- Certified Quality: All products adhere to strict safety and performance benchmarks.

- Technical Proficiency: Decades of experience in rubber engineering and manufacturing.

- Value and Reliability: Competitive pricing and dependable delivery.

- Comprehensive Support: Guidance from initial consultation through post-production.

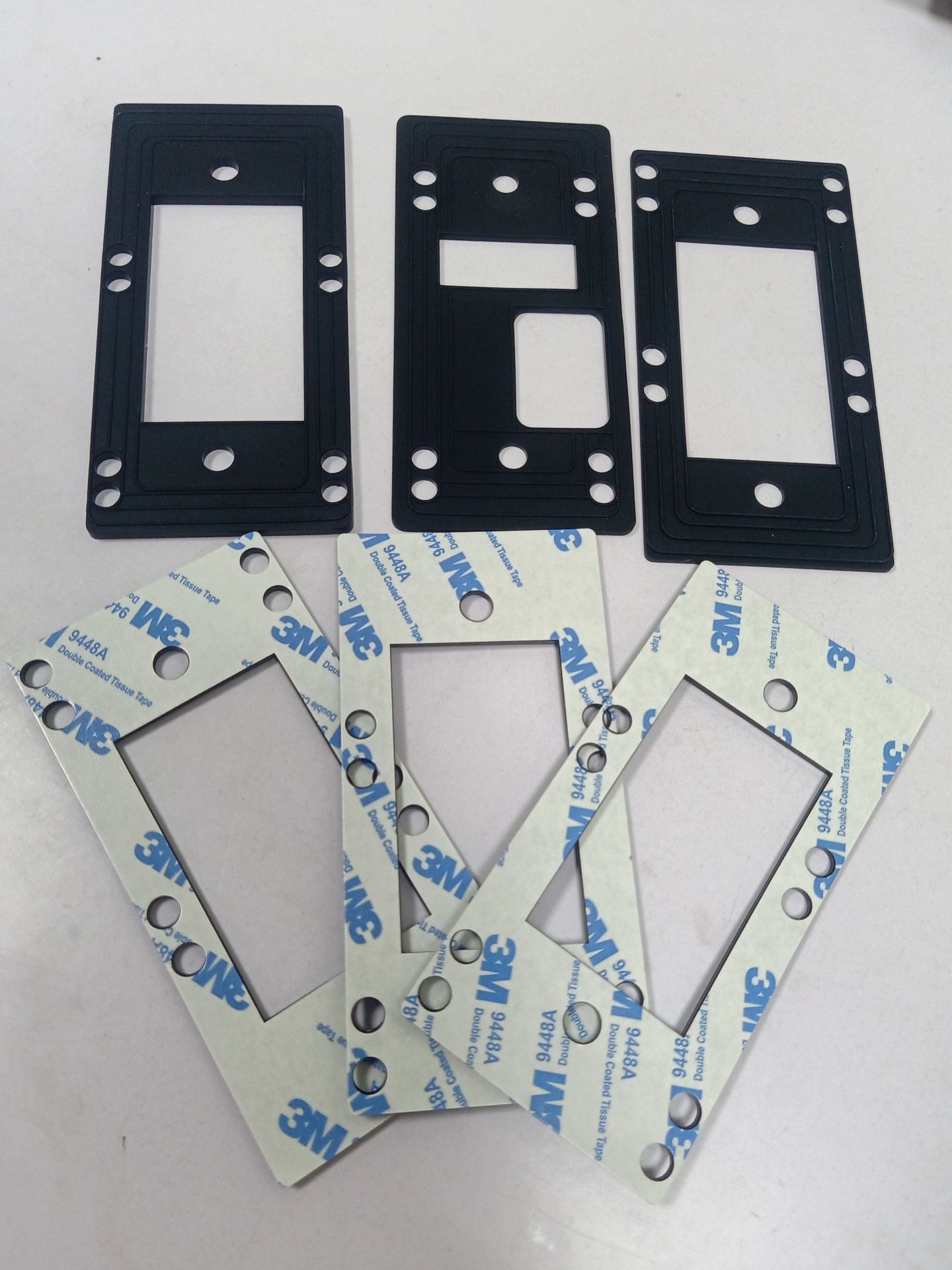

Custom Solutions for the Electronics Industry #

The electronics sector requires precision-engineered seals and components to protect sensitive instruments from environmental factors. Jhao Yang offers custom rubber solutions, working collaboratively with clients to:

- Understand the specific application and operational requirements.

- Select the most suitable rubber compound for optimal performance.

We invite you to explore the possibilities of electrical rubber and discover how our expertise can help you achieve greater safety, efficiency, and innovation in your products.